WEEK

SIXTEEN

Applications and Implications

Task for this week

This week we have to write about our project process and resourcess which we will use to make this. So i have to give the answer of some for this week.What will it do?

I am making a project which will check the liquid prepared in the kitchen and tell whether it is proper or not. It will measure the thinness and thickness of theliquid.I am creating this project right now to measure two things. First measuring sugar syrup in food lab and second measuring tomato ketchup in kitchen.

I am using motor in this project. When this motor rotates inside the liquid, it will take more current because shaft oppose the shear force of the liquid

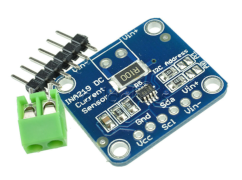

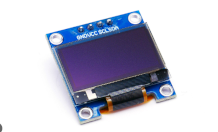

Then this current will be measured by the sensor and then we will see its data on the display.Before measuring both these things, I have to calibrate my project.

For that I will take perfect sugar strainer and tomato ketchup.And then I will rotate the machine inside them and note down the value of current. Then I will

give the condition in the microcontroller.Then whenever we measure these two liquid, it will give us the data by mixing it with the recorded current value.

Who's done what beforehand?

To measure the liquid consistency, there is a device called Rheometer which is available in the market. Along with this food product, many things are measured.

The way to do it is simple. There is a ring in its shaft which rotates through the liquid.When this rig rotates in the liquid, the force tightens due to which

the motor has to apply high torque and high current is required for high torque.So this gives the viscosity of the material according to the current and the shaft

rpm. The reason for this being very expensive, not everyone can buy, that's why I am designing my project by giving the principle of its current measurement.

My project will only be able to measure the consistency of some selected liquids.

Reference

What will you design ?

So I design a handi gadget whcih will circular in design. It will have a display at one side and have three condtional push button switch. There is part which willopen if we want to update the code or conditions.The project contains the motor , PCB boards, voltage regulator and oled display. The upper area consist a 12V female pin which is used to power supply. We will also give a on and off button

for the gadget at the side of power supply pin. I will also design a fin structure which easily fit with Motor shaft and this shaft rotate in the liquid food..

What materials and components will be used

The following component will be used in my project-• Power supply adapter- 12V 1A

• Microcontroller - Xiao ESP32c3 board

• Output devices - 12V motor, OLED I2C display , SMD LEDs

•Input Devices - Current sensor , Push buttons

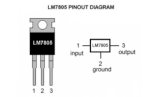

•IC- 7805 IC, 12V 30 A mosfet

Where will come from?

Some of these things are available in the local market like adapter and DC motor, But we have to buy sensor and other things online. So we bought sensor andother material from online websites. 3D printer fillaments and acrylic sheet for laser cut aLready avaialabe in the lab. Their purchase link are given in the below table.

How much will they cost?

| Name | Quantity | Price per unit | Total Price | Reference | Images |

|---|---|---|---|---|---|

| 12 V Female connector | 1 | Rs.20/- | Rs.20/- | Buy link |  |

| 7805 IC | 1 | Rs.50/- | Rs.50/- | Buy link |  |

| Xiao ESP32C3 | 1 | Rs.579/- | Rs.579/- | Buy link |  |

| 12V DC 200 RPM motor | 1 | Rs.219/- | Rs.219/- | Buy link |  |

| Current sensor INA219 | 1 | Rs.219/- | Rs.219/- | Buy link |  |

| Oled I2C display | 1 | Rs.230/- | Rs.230/- | Buy link |  |

| 5 MM lEDs | 4 | Rs.1/- | Rs.4/- | Buy link |  |

| 12 V Female connector | 5 | Rs.17/- | Rs.105/- | Buy link |  |

| 12V 1A adapter | 1 | Rs.199/- | Rs.199/- | Buy link |  |

| IRF3205 MOSFET | 1 | Rs.74/- | Rs.74/- | Buy link |  |

What parts and systems will be made?

So we have purchased all the material required for the project. The electronic designed is done with the xiao esp32c3 board. I am gomma make two pcbs, one have microcontroller and other have indicator leds and push button. The casing of the project will be made with the help of 3D printer. All the setup of component are inside the 3D printed casing. I will also use a 7805 voltage regulator to convert the voltage of 12V into 5V and then this 5V are supplied to the microcontroller biard. I'm going to laser cut 3mm acrylic tranparent sheet for the display safety. I have started to design the pcb board.What processes will be used?

The following processes will be used in my project-| Process | Tool | Used for | Machine Used |

|---|---|---|---|

| computer Aided design | SolidWorks | To design the project component and assembly | - |

| Computer Controlled Cutting | Inkscape | To cut the 3mm acrylic sheet for the display protection | Laser Cutting machine |

| 3D printing | Solidworks | Casig of the project | 3D printer |

| Electronic Design | Eagle | To design the PCB for the project | - |

| Electronic Production | Mods CE | To print the PCB | Roland SRM20 |

| Output Devices | DC motor, OLED display, LEDs | To show the output from microcontroller | - |

| Input Devices | Current Sensor, Push button | To give the signal to the microcontroller | - |

| Embedded programming | Arduino IDE | To Upload the code into microcontroller | - |

| Input Devices | Current Sensor, Push button | To give the signal to the microcontroller | - |

What questions need to be answered?

-The Program you upload is give the proper output by reading the data from input device.-Is the measure accurate current or give some variation?

-Is Motor able to rotate in highly thick liquid

-How you control the motor?

-Are you connect 3d printed part in the machine shaft?